refractory solutions

at it’s best

Discover how intco works, by clicking the segments of our service circle below.

The perfect quality of all our products is intco’s ultimate target. In order to keep this promise we perform extensive quality control during the course of the entire production process.

Basis for this work is our knowledge about refractory production, refractory testing and refractory market. In the beginning of our co-operation with manufacturers stands a complete analysis of the producer.

Manufacturers of intco materials are prudently chosen and we carefully build up business with new suppliers by means of steadily growing order volumes. During the initial phase we establish the specifications and advance the quality level.

It’s mandatory for us and our manufacturers to adhere to a time schedule while maintaining high quality standards.

And as a final step, we assure secure and fast shipping to the end user.

INTCO’S SERVICE CIRCLE,

THINK AND ACT CONSCIOUSLY

Enables quick decisions, saves time and money.

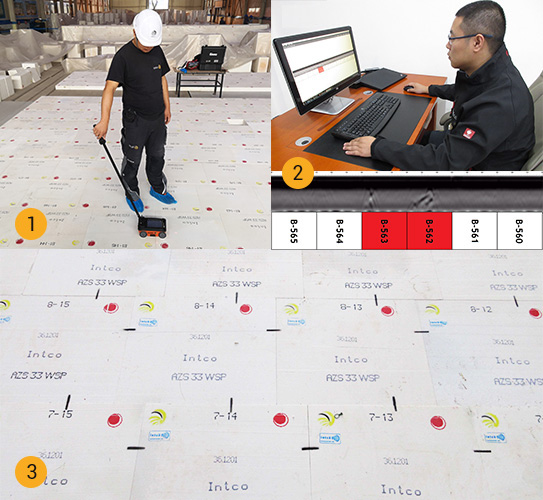

Picture 1

Thanks to a High Definition Ground Penetrating Radar connected with a high-resolution display in the device, now decisions about the further use of the block can be done still more precisely.

Picture 2

For the most important furnace parts a GPR inspection report will be provided, which connects high resolution images with the pre-assembly number in the furnace part drawing in a very quick and easy way.

Picture 3

Successfully inspected blocks will be marked by our inspection stamp.

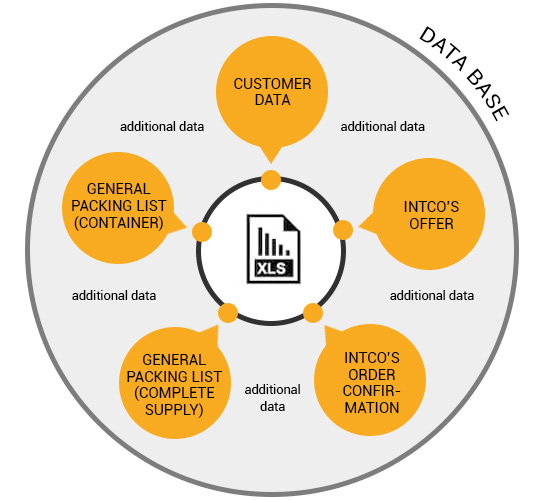

Furnace designers prepare their bill of material in MS Office documents or at least have a software module to export the generated bill of material to a MS Office compatible file format.

Since we dispense with an enterprise system, we can process the received data 1:1 and hence, eliminate the risk of typo errors.

Our offer becomes an order confirmation. Our order confirmation becomes the bill of material for the contract to the manufacturers. The bill of material also serves as basis for our GENERAL PACKINST LIST and thereof as the single packinst lists for our forwarders and customer.

From the offer to the dispatch of goods all data remains unchanged, additional data about pre-assembly, packaging and transport will be added. Finally, a database for each single project arises and we will be enabled to respond to your individual questions and requirements quickly and at any time.

Each refractory material has its different physical and chemical properties. Each transport route has its specific impact on the refractory material (condition of streets, rough sea, climate, etc.).

intco consciously develops and establishes new packaging types and a suitable cargo safety in order to secure the goods’ arrival at destination without breakage.

International standards like ISPM-15 for wooden packaging will be considered to promote a smooth import of the goods.

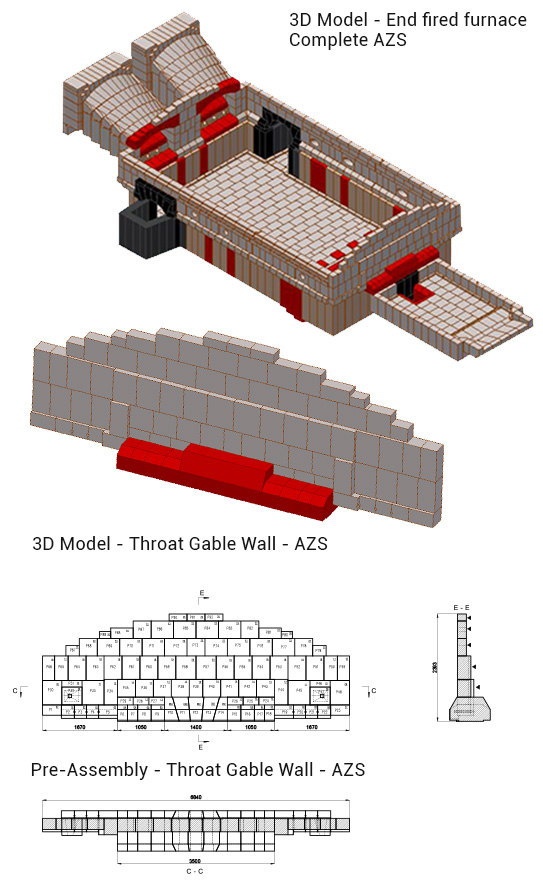

If a 3D furnace design is available, intco provides FULL 3D-INTEGRATION. The 3D-files are basis for

This procedure avoids mistakes in computer aided design and shortens the delivery time considerably.

As service provider between our esteemed customers and all the manufacturers, we manage a lot of interfaces, to assure that all the refractory products arrive the destination in good condition, right construction sequence and due course. Our staff achieves this high-performance in logistics by working in an environment organized on high level and making use of well-established quality standards and methods.

See our 3D models of conventional glass-melting furnaces and find out which material grade suits your requirements most. View our furnace impression of an end-fired furnace, of a float furnace and a recuperative furnace.

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from X. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information